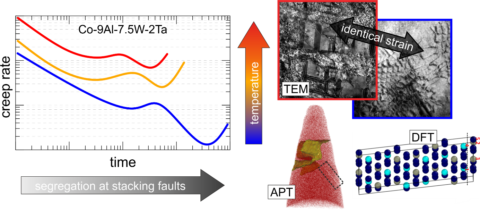

New collaborative publication: Understanding creep of a single-crystalline Co-Al-W-Ta superalloy by studying the deformation mechanism, segregation tendency and stacking fault energy

A new publication entitled “Understanding creep of a single-crystalline Co-Al-W-Ta superalloy by studying the deformation mechanism, segregation tendency and stacking fault energy” was recently published in Acta Materialia. This nice collaboration of various project partners of the SFB/TR103 and the high-temperature materials group combines creep, SEM, TEM, APT and DFT calculations in this correlative study performed by researchers from WWI, the Ruhr-Universität Bochum, the ICAMS Bochum and the Max-Planck-Institut für Eisenforschung. Please find the abstract below and the full version via the following links:

https://doi.org/10.1016/j.actamat.2021.117019

https://arxiv.org/abs/2105.14725

A systematic study of the compression creep properties of a single-crystalline Co-base superalloy (Co-9Al-7.5W-2Ta) was conducted at 950, 975 and 1000 °C to reveal the influence of temperature and the resulting diffusion velocity of solutes like Al, W and Ta on the deformation mechanisms. Two creep rate minima are observed at all temperatures indicating that the deformation mechanisms causing these minima are quite similar. Atom-probe tomography analysis reveals elemental segregation to stacking faults, which had formed in the γ‘ phase during creep. Density-functional-theory calculations indicate segregation of W and Ta to the stacking fault and an associated considerable reduction of the stacking fault energy. Since solutes diffuse faster at a higher temperature, segregation can take place more quickly. This results in a significantly faster softening of the alloy, since cutting of the γ‘ precipitate phase by partial dislocations is facilitated through segregation already during the early stages of creep. This is confirmed by transmission electron microscopy analysis. Therefore, not only the smaller precipitate fraction at higher temperatures is responsible for the worse creep properties, but also faster diffusion-assisted shearing of the γ‘ phase by partial dislocations. The understanding of these mechanisms will help in future alloy development by offering new design criteria.